CNC Automation Products

3 Axis Milling Controller-2000 Series

TAC-2003M Milling controller(TAC2003M, TAC2004M, TAC2005M) is a high quality CNC system. It is the upgraded version of TAC1000M series, it supports milling, boring and drilling cycle. It employs 64 bits high-capability CPU and very large scale programmable device FPGA, applies real-time multi-task control technology and hardware interpolation

Features:

- 3 axis movement, any 2 axis circular interpolation, any 3 axis linear interpolation

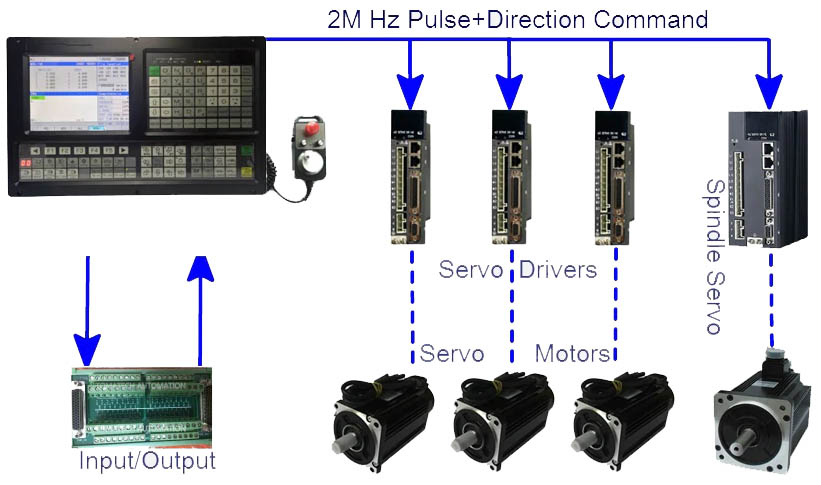

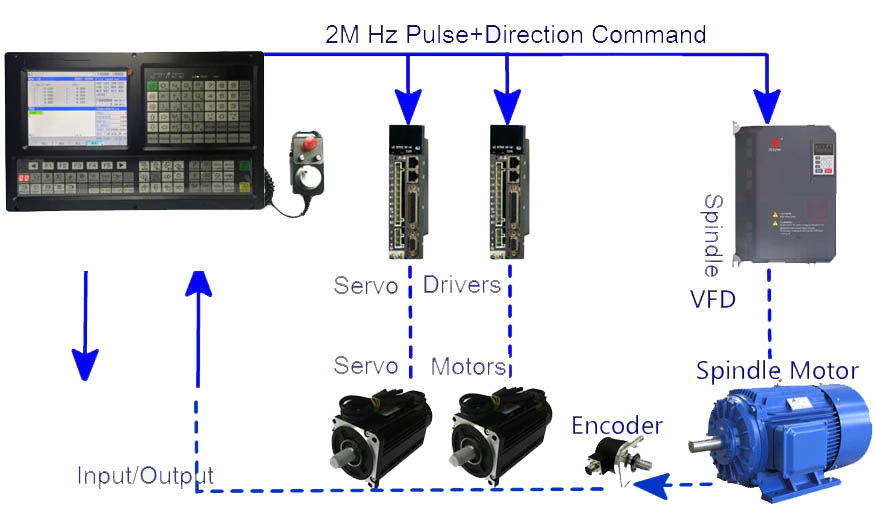

- 3 stepper / servo motor control; Step(Pulse) + Direction Command.

- 2 channels 0-10v analog spindle

- Speed prospect processing, can get a smooth tool path,especially for engraving,milling

- Support linear tool magazine, umbrella tool magazine, and other type of tool magazine can be customized

- System-self diagnose and parameters backup, recovery function;

- Support USB;

- Support MPG;

- G code track preview, real-time tracking and syntax check function

Usual function:

- Pulse frequency up to 2M;

- 37 input and 37 output ports;

- 2-channel 0-10v analog output Control for VFD or Spindle servo driver

- support DNC processing

-

|

Number of control axes |

3axes (X, Y, Z) |

|

Minimum programming |

0.001mm |

|

Maximum programming |

± 99999.999mm |

|

Maximum traverse speed |

30m / min |

|

Feed speed |

0.001-15m / min |

|

Manual continuous |

one axis or simultaneous multi-axis |

|

Interpolation |

straight line, arc, thread interpolation |

|

Tool offset |

length compensation, nose radius C compensation |

|

Spindle functions |

gear, dual analog control, rigid tapping |

|

Handwheel functions |

panel type, plug-in hand-held |

|

Screen saver function |

screen saver function |

|

Communication function |

RS232, U disk interface |

|

Compensation function |

Tool compensation, Pitch compensation, radius compensation |

|

Program editing |

Relative / absolute programming |

|

Limit function |

software limit, hardware limit |

|

Pre-reading function |

Short line preprocessing 10,000 lines |

|

Password protection |

multi-level password protection |

|

Input and output |

I / O point 37 / 37 |

|

PLC programming |

Programable PLC function |

|

Acceleration and deceleration control |

linear acceleration and deceleration, the number of additions and subtractions |

|

Encoder lines |

any setting |

|

User macro program |

Yes |

|

Electronic gear functions |

Yes |

|

ATC |

Umbrella / Disk Linear tool changer |

|

Applicable machine tools |

milling machine, boring machine, drilling machine |

4 Axis Milling Controller-2000 Series

TAC-2000M Series Milling controller(TAC2003M, TAC2004M, TAC2005M) is a high quality CNC system. It is the upgraded version of TAC1000M series, it supports milling, boring and drilling cycle. It employs 64 bits high-capability CPU and very large scale programmable device FPGA, applies real-time multi-task control technology and hardware interpolation

Characteristics:

●Three axes control; 3-5 axes linkage; 2 analog spindles

●1ms interpolation cycle, 0.1μm control precision.

●Two channels -10V ~ 10V analog voltage output, support double spindle control

●Linear type, index type and S type etc. acceleration and deceleration types can be chosen.

●Embedded with PLC programming, the current running PLC programming can be chosen

●PLC displayed online, real time monitoring, signal real time tracing

●Supports statement type macro programming, supports macro codes with parameters calls.

●Flexible tapping and rigid tapping can be set by parameters

● Includes spiral, scaling, polar coordinate, fixed circle and a variety of slotting compound cycle function.

●Includes historical alarm and resumen operation functions, it’s convenient for users to operate and maintenance.

● Support multi-level passwords for equipment maintenance and management

● 36 point general input/36 point general output

●Support standard RS232 and USB port, support U disk documents operation, system configuration and software updated, it can meet the functions that documents transfer, serial ports DNC machining and USB online machining.

Display interface:

● 8.0 inch wide-screen LCD, 800×480 lattice

● Chinese, English language display

● 2D tool path displays.

● Real-time clock

Operation mode:

● Operation modes: edit, automatic, input, machine tool reset, handwheel/single-step, manual, DNC.

● Multiple operateauthority management.

● Alarm logging

Program edit:

● Program volumn: 56MB, it can store 400 programmings mostly (includes sub-programming, Marco programming)

● Edit function: Programming/programming segment/word retrieval, amend, delete, copy, and stick

● Programming format: ISO code,supports statement macro program, supports relative coordinate, absolute

coordinate and polar coordinate.

● Programming calls: supports maco with parameters calls, level 4 subprogram nesting.

Communication function:

● RS232: parts program, parameters and some documentation two-way transmission, supports PLC program, system

software serial ports update.

● USB: U disk documentation operatiom, U disk processing directly, Support PLC program, system software U disk

update.

● Support serial port DNC processing function and USB online processing function, reliability and safty

Relability and safty function

● Emergency stop

● Handware route limit

● Software routet inspect

● Data backups and Data recover.

Control axis:

● Control axis: 3-5 axis (X, Y, Z,A,B)

● Linkage axis: 3-5 axis Feeding axis functions

● Position command range:

Metric input (G21) -9999.9999mm ~9999.9999mm, the mininum command unit: 0.0001mm

Inch input (G20): -999.9999inch ~999.9999inch, the mininum command unit: 0.0001inch

● Electronic gear ration: command multiplier 1 ~ 65536, command multiplier1 ~65536

● Rapid traverse speed: maximum 60m/min

● Rapid traverse override: F0, 25%, 50%, 100% four levels real-time tuning

● Cutting feedrate: maximum feeding speed: maximum 15m/min (G94) or 500.00mm/r (G95)

● Feedrate override: 0 ~ 150% sixteen-level real-time tuning

● Manual feedrate: 0 ~ 150% sixteen-level real time tuning

● MPG feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Single step feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Interpolation mode: linear interpolation, arc interpolation, spiral interpolation and ragid rapping

● Automatic chamfering function

Acceleration/deceleration types:

● Cutting feeding: before the acceleration and deceleration linear type, before the acceleration and deceleration S

type, after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

● Fast moving: before the acceleration and deceleration linear type, before the acceleration and deceleration S type,

after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

●System with preview function, it can read 15 NC programming, make small line interpolation in high speed and

smooth, it’s suit for components machine toolings processing.

● The original speed of acceleration and deceleration, end speed and acceleration&deceleration speed set by

parameters.

● Manual mode, handwheel mode is after acceleration and deceleration control, handwheel mode can choose

emergency mode or full operation mode.

● Rapid positioning can choose linear or broken line.

Spindle axis functions:

● Two channels -10V ~ 10V analog voltage output, support double spindle control

● Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

● Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

● Spindle ration: 50% ~ 120% eight stages real-time tunning in total

● Spindle axis constant line speed control

● Tapping circle, rigid tapping

Tool functions:

● Tool length compensation

● Tool point radius compensation (C type)

Precision compensation:

●Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can

be set.

●Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed

mode.

PLC functions:

● Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the f

irst level programming is 8ms.

● Support PLC warning and PLC alarm.

● Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

● 45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

● I/O unit input/output: 36/36

|

Function |

Code |

Function |

|

|

G00 |

Positioning (rapid traverse) |

G51 |

Scaling |

|

G01 |

Linear interpolation (cutting feed) |

G53 |

Mechanical coordinate system |

|

G02 |

Circular interpolation CW (clockwise) |

G54 |

Workpiece coordinate system1 |

|

G03 |

Circular interpolation CCW(anticlockwise) |

G55 |

Workpiece coordinate system2 |

|

G04 |

Delay, exact stop |

G56 |

Workpiece coordinate system3 |

|

G12 |

Store rount detection function connected |

G57 |

Workpiece coordinate system4 |

|

G13 |

Store rount detection function broken |

G58 |

Workpiece coordinate system5 |

|

G15 |

Cancel polar coordinate instruction |

G59 |

Workpiece coordinate system6 |

|

G16 |

Polar coordinate instruction |

G54.1-G54.50 |

|

|

G17 |

XY plane selection |

G60 |

Single direction positioning |

|

G18 |

ZX plane selection |

G61 |

Orientation mode |

|

G19 |

YZ plane selection |

G62 |

Automatic corner ratio |

|

G20 |

Inch input |

G63 |

Tapping mode |

|

G21 |

Metric input |

G64 |

Cutting mode |

|

G22 |

Anticlockwise circle internel groove milling |

G65 |

Marco instruction |

|

G23 |

Clockwise circle interner groove milling |

G68 |

Coordination rotation |

|

G24 |

Anticlockwise entire circle finish-groove milling |

G69 |

Coordination rotation cancel |

|

G25 |

Clockwise entire circle finish-groove milling |

G73 |

High speed deep hole processing cycle |

|

G26 |

Anticlockwise circle external finish-groove milling |

G74 |

Left rotation tapping cycle |

|

G27 |

Reference position return checking |

G76 |

Fine boring cycle |

|

G28 |

Return to reference position |

G80 |

Fixed cycle cancel |

|

G29 |

Return from reference point |

G81 |

Drilling cycle (spot drilling cycle ) |

|

G30 |

Return to 2, 3, 4 reference point |

G82 |

Drilling cycle, point boring cycle |

|

G31 |

Skip function |

G83 |

Chip removal drilling cycle |

|

G32 |

Clockwise external circle external finish-groove milling |

G84 |

Right rotation tapping cycle |

|

G33 |

Clockwise tangle groove milling |

G85 |

Boring cycle |

|

G34 |

Anticlockwise tangle groove milling |

G86 |

Boring cycle |

|

G35 |

Anticlockwise tangle internal finish-groove milling |

G87 |

Back boring cycle |

|

G36 |

Clockwise tangle internal finish-groove milling |

G88 |

Boring cycle |

|

G37 |

Anticlockwise tangle external finish groove milling |

G89 |

Boring cycle |

|

G38 |

Clockwise tangle external finish groove milling |

G90 |

Absolute programing |

|

G39 |

Corner offset circle interpolation |

G91 |

Relative programing |

|

G40 |

Tool radius offset cancel |

G92 |

floating coordinate system setting |

|

G41 |

Left tool radius offset |

G94 |

Feeding/min |

|

G42 |

Right tool radius offset |

G95 |

Feeding/rpm |

|

G43 |

Positive tool radius offset |

G96 |

Constant speed control (cutting speed) |

|

G44 |

Negative tool radius offset |

G97 |

Constant speed control cancel (cutting speed) |

|

G49 |

Tool length offset cancle |

G98 |

Return original plane |

|

G50 |

Ratio zoom cancel |

G99 |

Return R point plane |

5 Axis Milling Controller-2000 Series

TAC-2005M Milling controller is a new generation of CNC system. As the upgraded version, it supports milling, boring and drilling cycle. It employs 32 bits high-capability CPU and very large scale programmable device FPGA, applies real-time multi-task control technology and hardware interpolation technology, and is able to perform mum level precisionmotion control and PLC logic control

-

Characteristics:

●Three axes control; 5 axes linkage; 2 analog spindles

●1ms interpolation cycle, 0.1μm control precision.

●Two channels -10V ~ 10V analog voltage output, support double spindle control

●Linear type, index type and S type etc. acceleration and deceleration types can be chosen.

●Embedded with PLC programming, the current running PLC programming can be chosen

●PLC displayed online, real time monitoring, signal real time tracing

●Supports statement type macro programming, supports macro codes with parameters calls.

●Flexible tapping and rigid tapping can be set by parameters● Includes spiral, scaling, polar coordinate, fixed circle

and a variety of slotting compound cycle function.

●Includes historical alarm and resumen operation functions, it’s convenient for users to operate and maintenance.

● Support multi-level passwords for equipment maintenance and management

● 36 point general input/36 point general output

●Support standard RS232 and USB port, support U disk documents operation, system configuration and software

updated, it can meet the functions that documents transfer, serial ports DNC machining and USB online machining

-

Control axis:

● Control axis: 5 axis (X, Y, Z,4th,5th)

● Linkage axis: 5 axis Feeding axis functions

● Position command range:

Metric input (G21) -9999.9999mm ~9999.9999mm, the mininum command unit: 0.0001mm

Inch input (G20): -999.9999inch ~999.9999inch, the mininum command unit: 0.0001inch

● Electronic gear ration: command multiplier 1 ~ 65536, command multiplier1 ~65536

● Rapid traverse speed: maximum 60m/min

● Rapid traverse override: F0, 25%, 50%, 100% four levels real-time tuning

● Cutting feedrate: maximum feeding speed: maximum 15m/min (G94) or 500.00mm/r (G95)

● Feedrate override: 0 ~ 150% sixteen-level real-time tuning

● Manual feedrate: 0 ~ 150% sixteen-level real time tuning

● MPG feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Single step feeding: 0.001mm, 0.01mm, 0.1mm, 1mm four gears

● Interpolation mode: linear interpolation, arc interpolation, spiral interpolation and ragid rapping

● Automatic chamfering function

Acceleration/deceleration types:

● Cutting feeding: before the acceleration and deceleration linear type, before the acceleration and deceleration S

type, after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

● Fast moving: before the acceleration and deceleration linear type, before the acceleration and deceleration S type,

after the acceleration and deceleration linear type and after the acceleration and deceleration index type.

●System with preview function, it can read 15 NC programming, make small line interpolation in high speed and

smooth, it’s suit for components machine toolings processing.

● The original speed of acceleration and deceleration, end speed and acceleration&deceleration speed set by

parameters.

● Manual mode, handwheel mode is after acceleration and deceleration control, handwheel mode can choose

emergency mode or full operation mode.

● Rapid positioning can choose linear or broken line.

Spindle axis functions:

● Two channels -10V ~ 10V analog voltage output, support double spindle control

● Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

● Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

● Spindle ration: 50% ~ 120% eight stages real-time tunning in total

● Spindle axis constant line speed control

● Tapping circle, rigid tapping

Tool functions:

● Tool length compensation

● Tool point radius compensation (C type)

Precision compensation:

●Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can

be set.

●Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed

mode.

PLC functions:

● Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the f

irst level programming is 8ms.

● Support PLC warning and PLC alarm.

● Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

● 45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

● I/O unit input/output: 36/36

Display interface:● 7.0 inch wide-screen LCD, 800×480 lattice

● Chinese, English etc multiply language display

● 2D tool path displays.

● Real-time clock

Operation mode:

● Operation modes: edit, automatic, input, machine tool reset, handwheel/single-step, manual, DNC.

● Multiple operateauthority management.

● Alarm logging

Program edit:

● Program volumn: 56MB, it can store 400 programmings mostly (includes sub-programming, Marco programming)

● Edit function: Programming/programming segment/word retrieval, amend, delete, copy, and stick

● Programming format: ISO code,supports statement macro program, supports relative coordinate, absolute

coordinate and polar coordinate.

● Programming calls: supports maco with parameters calls, level 4 subprogram nesting.

Communication function:

● RS232: parts program, parameters and some documentation two-way transmission, supports PLC program, system

software serial ports update.

● USB: U disk documentation operatiom, U disk processing directly, Support PLC program, system software U disk

update.

● Support serial port DNC processing function and USB online processing function, reliability and safty

Relability and safty function

● Emergency stop

● Handware route limit

● Software routet inspect

● Data backups and Data recover.

-

Display interface:

● 7.0 inch wide-screen LCD, 800×480 lattice

● Chinese, English etc multiply language display

● 2D tool path displays.

● Real-time clock

Operation mode:

● Operation modes: edit, automatic, input, machine tool reset, handwheel/single-step, manual, DNC.

● Multiple operateauthority management.

● Alarm logging

Program edit:

● Program volumn: 56MB, it can store 400 programmings mostly (includes sub-programming, Marco programming)

● Edit function: Programming/programming segment/word retrieval, amend, delete, copy, and stick

● Programming format: ISO code,supports statement macro program, supports relative coordinate, absolute

coordinate and polar coordinate.

● Programming calls: supports maco with parameters calls, level 4 subprogram nesting.

Communication function:

● RS232: parts program, parameters and some documentation two-way transmission, supports PLC program, system

software serial ports update.

● USB: U disk documentation operatiom, U disk processing directly, Support PLC program, system software U disk

update.

● Support serial port DNC processing function and USB online processing function, reliability and safty

Relability and safty function

● Emergency stop

● Handware route limit

● Software routet inspect

● Data backups and Data recover.

|

Function |

Code |

Function |

|

|

G00 |

Positioning (rapid traverse) |

G51 |

Scaling |

|

G01 |

Linear interpolation (cutting feed) |

G53 |

Mechanical coordinate system |

|

G02 |

Circular interpolation CW (clockwise) |

G54 |

Workpiece coordinate system1 |

|

G03 |

Circular interpolation CCW(anticlockwise) |

G55 |

Workpiece coordinate system2 |

|

G04 |

Delay, exact stop |

G56 |

Workpiece coordinate system3 |

|

G12 |

Store rount detection function connected |

G57 |

Workpiece coordinate system4 |

|

G13 |

Store rount detection function broken |

G58 |

Workpiece coordinate system5 |

|

G15 |

Cancel polar coordinate instruction |

G59 |

Workpiece coordinate system6 |

|

G16 |

Polar coordinate instruction |

G54.1-G54.50 |

|

|

G17 |

XY plane selection |

G60 |

Single direction positioning |

|

G18 |

ZX plane selection |

G61 |

Orientation mode |

|

G19 |

YZ plane selection |

G62 |

Automatic corner ratio |

|

G20 |

Inch input |

G63 |

Tapping mode |

|

G21 |

Metric input |

G64 |

Cutting mode |

|

G22 |

Anticlockwise circle internel groove milling |

G65 |

Marco instruction |

|

G23 |

Clockwise circle interner groove milling |

G68 |

Coordination rotation |

|

G24 |

Anticlockwise entire circle finish-groove milling |

G69 |

Coordination rotation cancel |

|

G25 |

Clockwise entire circle finish-groove milling |

G73 |

High speed deep hole processing cycle |

|

G26 |

Anticlockwise circle external finish-groove milling |

G74 |

Left rotation tapping cycle |

|

G27 |

Reference position return checking |

G76 |

Fine boring cycle |

|

G28 |

Return to reference position |

G80 |

Fixed cycle cancel |

|

G29 |

Return from reference point |

G81 |

Drilling cycle (spot drilling cycle ) |

|

G30 |

Return to 2, 3, 4 reference point |

G82 |

Drilling cycle, point boring cycle |

|

G31 |

Skip function |

G83 |

Chip removal drilling cycle |

|

G32 |

Clockwise external circle external finish-groove milling |

G84 |

Right rotation tapping cycle |

|

G33 |

Clockwise tangle groove milling |

G85 |

Boring cycle |

|

G34 |

Anticlockwise tangle groove milling |

G86 |

Boring cycle |

|

G35 |

Anticlockwise tangle internal finish-groove milling |

G87 |

Back boring cycle |

|

G36 |

Clockwise tangle internal finish-groove milling |

G88 |

Boring cycle |

|

G37 |

Anticlockwise tangle external finish groove milling |

G89 |

Boring cycle |

|

G38 |

Clockwise tangle external finish groove milling |

G90 |

Absolute programing |

|

G39 |

Corner offset circle interpolation |

G91 |

Relative programing |

|

G40 |

Tool radius offset cancel |

G92 |

floating coordinate system setting |

|

G41 |

Left tool radius offset |

G94 |

Feeding/min |

|

G42 |

Right tool radius offset |

G95 |

Feeding/rpm |

|

G43 |

Positive tool radius offset |

G96 |

Constant speed control (cutting speed) |

|

G44 |

Negative tool radius offset |

G97 |

Constant speed control cancel (cutting speed) |

|

G49 |

Tool length offset cancle |

G98 |

Return original plane |

|

G50 |

Ratio zoom cancel |

G99 |

Return R point plane |

Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce sagittis, massa fringilla consequat blandit, mauris ligula porta nisi, non tristique enim sapien vel nisl. Suspendisse vestibulum lobortis dapibus. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae;

|

Function |

Code |

Function |

|

|

G00 |

Positioning (rapid traverse) |

G51 |

Scaling |

|

G01 |

Linear interpolation (cutting feed) |

G53 |

Mechanical coordinate system |

|

G02 |

Circular interpolation CW (clockwise) |

G54 |

Workpiece coordinate system1 |

|

G03 |

Circular interpolation CCW(anticlockwise) |

G55 |

Workpiece coordinate system2 |

|

G04 |

Delay, exact stop |

G56 |

Workpiece coordinate system3 |

|

G12 |

Store rount detection function connected |

G57 |

Workpiece coordinate system4 |

|

G13 |

Store rount detection function broken |

G58 |

Workpiece coordinate system5 |

|

G15 |

Cancel polar coordinate instruction |

G59 |

Workpiece coordinate system6 |

|

G16 |

Polar coordinate instruction |

G54.1-G54.50 |

|

|

G17 |

XY plane selection |

G60 |

Single direction positioning |

|

G18 |

ZX plane selection |

G61 |

Orientation mode |

|

G19 |

YZ plane selection |

G62 |

Automatic corner ratio |

|

G20 |

Inch input |

G63 |

Tapping mode |

|

G21 |

Metric input |

G64 |

Cutting mode |

|

G22 |

Anticlockwise circle internel groove milling |

G65 |

Marco instruction |

|

G23 |

Clockwise circle interner groove milling |

G68 |

Coordination rotation |

|

G24 |

Anticlockwise entire circle finish-groove milling |

G69 |

Coordination rotation cancel |

|

G25 |

Clockwise entire circle finish-groove milling |

G73 |

High speed deep hole processing cycle |

|

G26 |

Anticlockwise circle external finish-groove milling |

G74 |

Left rotation tapping cycle |

|

G27 |

Reference position return checking |

G76 |

Fine boring cycle |

|

G28 |

Return to reference position |

G80 |

Fixed cycle cancel |

|

G29 |

Return from reference point |

G81 |

Drilling cycle (spot drilling cycle ) |

|

G30 |

Return to 2, 3, 4 reference point |

G82 |

Drilling cycle, point boring cycle |

|

G31 |

Skip function |

G83 |

Chip removal drilling cycle |

|

G32 |

Clockwise external circle external finish-groove milling |

G84 |

Right rotation tapping cycle |

|

G33 |

Clockwise tangle groove milling |

G85 |

Boring cycle |

|

G34 |

Anticlockwise tangle groove milling |

G86 |

Boring cycle |

|

G35 |

Anticlockwise tangle internal finish-groove milling |

G87 |

Back boring cycle |

|

G36 |

Clockwise tangle internal finish-groove milling |

G88 |

Boring cycle |

|

G37 |

Anticlockwise tangle external finish groove milling |

G89 |

Boring cycle |

|

G38 |

Clockwise tangle external finish groove milling |

G90 |

Absolute programing |

|

G39 |

Corner offset circle interpolation |

G91 |

Relative programing |

|

G40 |

Tool radius offset cancel |

G92 |

floating coordinate system setting |

|

G41 |

Left tool radius offset |

G94 |

Feeding/min |

|

G42 |

Right tool radius offset |

G95 |

Feeding/rpm |

|

G43 |

Positive tool radius offset |

G96 |

Constant speed control (cutting speed) |

|

G44 |

Negative tool radius offset |

G97 |

Constant speed control cancel (cutting speed) |

|

G49 |

Tool length offset cancle |

G98 |

Return original plane |

|

G50 |

Ratio zoom cancel |

G99 |

Return R point plane |

4 Axis Turning Controller-2000 Series

TAC-2000T is a new generation CNC turning controller, It based ARM9+FPAG large scale CPU and processor ,8" TFT display,Meet 2 -5 Axes lathe machine. this controller support ISO G codes, Macro program and PLC ladder, very flexible for unstandard function design.

Control Axes:

1. Control axes: 2 -5 axes (X, Z,Y ,A, B)

2. Interpolation axes: X, Z, A ,B linear interpolation; X and Z or any two axes arc interpolation;

Feeding axis function:

1. Minimum command unit: 0.001mm or 0.0001mm can be selected

2. Position command range: ±99999999 × minimum command unit

3. Rapid traverse speed: When the command unit is 0.001mm, the maximum speed is 60m/min; (0.0001mm,

the maximum speed is 24m/min)

4. Rapid override: F0, 25%, 50% and 100%, total four levels, real-time adjustment;

5. Feeding override: total 16 levels: 0~150%, real-time adjustment;

6. Interpolation mode: linear, arc and spiral interpolation and rigid tapping

7. Auto chamfering

Acceleration and deceleration function:

1. Cutting feeding: Acceleration or deceleration in linear type/index type or front/rear is selectable.

2. Rapid traverse: Acceleration or deceleration in linear type/index type or front/rear is selectable.

3. Tapping: Acceleration or deceleration in linear type/index type or front/rear is selectable.

4. The starting speed, finishing speed and time of acceleration and deceleration are set by the parameter.

Spindle function:

1. Analog voltage 0V~10V output in two channels, support two-spindle control

2. Spindle encoder feed back in one channel, the resolution of spindle encoder can be set (0 or 100p/r~5000p/r)

3. Transmission ratio between encoder and spindle is:(1~255):(1~255)

4. Spindle speed: It is specified by S code or PLC signal, the speed range is 0rpm~9999rpm.

5. Spindle override: total 8 levels: 50%~120%, real-time adjustment

6. Spindle constant surface speed control

7. Tapping cycle/rigid tapping

Tool function:

1. Tool length compensation

2. Tool radius compensation (C type)

3. Tool wearing compensation

4. Tool life management

Precision compensation:

1. Backlash compensation

2. Pitch error compensation in memory type

PLC function:

1. PLC program in two levels, maximum 5,000 steps, the refresh cycle of the 1st level program: 8ms.

2. PLC program communication download

3. Support PLC warning and PLC alarm

4. Support many PLC programs (maximum 16), the current running PLC program can be selected

5. Basic I/O: input in 24 points/output in 24 points

Man-machine interface:

1. 8″large screen LCD, the resolution is 800×600

2. Display in Chinese, English Language

3. Display in processing path and it can real-time zoom in and out, translation and scroll lock.

4. Real-time clock

Operation management:

1. Operation mode: Edit, auto, MDI, machine zero-return, MPG/single step, manual and DNC.

2. Operation authority of multiple levels management

3. Alarm record

Editing program:

1. Program capacity: 40M, 10,000 programs (including subprograms, macro programs)

2. Editing function: program/block/characters research, rewrite and delete

3. Program format: ISO code, support macro command programming in sentence type

4. Calling program: It supports macro program with parameter, subprogram nesting of 4 layers

Communication function:

1. RS232: Files of part program and parameter, etc can be transmitted in two-way, DNC real-time processing, s

upport PLC program, serial ports of system software upgrade.

2. USB: File operation, directly processing files, support PLC program, system software upgrade in flash disc.

Safety function:

1. Emergency stop

2. Hardware travel limit

3. Software travel limit

4. Data restoring and recovering

|

code |

Function |

code |

function |

|

G00 |

Rapid traverse(positioning) |

G50 |

Float coordinate setting |

|

G01 |

Linear Interpolation |

G54-G59 |

Set workpiece coordinate |

|

G02 |

Clockwise circular interpolation |

G65 |

Macro calling(no modal) |

|

G03 |

Anti-clockwise circular interpolation |

G71 |

Axial roughing cycle |

|

G04 |

Pause/ Orientation |

G72 |

Radial roughing cycle |

|

G17 |

Plane selection |

G73 |

Closed cutting cycle |

|

G18 |

Plane selection |

G70 |

Finishing cutting cycle |

|

G19 |

Plane selection |

G74 |

Axial grooving cycle |

|

G10 |

Data input available |

G75 |

Radial roughing cycle |

|

G11 |

Data input cacel |

G76 |

Multiple threading cutting |

|

G20 |

Inch unit |

G80 |

Rigid tapping status cancel |

|

G21 |

Metric input |

G84 |

Axial rigid tapping |

|

G28 |

Return to home position |

G88 |

Radial rigid tapping |

|

G30 |

Return to machine 2,3,4 ref.point |

G90 |

Axial cutting cycle |

|

G31 |

Skip function |

G92 |

Threading cycle |

|

G32 |

Constant pitch threading |

G94 |

Radial cutting cycle |

|

G33 |

Z axes tapping cycle |

G96 |

Constant speed cutting |

|

G34 |

Variable pitch threading |

G97 |

Constant speed cutting cancel |

|

G40 |

Cancel tool nose radius compensation |

G98 |

Feed per minute |

|

G41 |

Left tool nose radius compensation |

G99 |

Feed per revolution |

|

G42 |

Right tool nose radius compensation |

|

|

3 Axis Turning Controller-2000 Series

TAC-2003T is a new generation CNC turning controller, It based ARM9+FPAG large scale CPU and processor , 8" TFT display,Meet 2 -5 Axes lathe machine. this controller support ISO G codes, Macro program and PLC ladder, very flexible for unstandard function design.

Features:

- 3 axis movement, any 2 axis circular interpolation, any 3 axis linear interpolation

- 3 stepper / servo motor control; Step(Pulse) + Direction Command.

- 2 channels 0-10v analog spindle

- Speed prospect processing, can get a smooth tool path,especially for engraving,milling

- Support linear tool changer, 4-12 tools turret , and other type of tool changer can be customized

- System-self diagnose and parameters backup, recovery function;

- Support USB;

- Support MPG;

- G code track preview, real-time tracking and syntax check function

Usual function:

- Pulse frequency up to 2M;

- 24 input and 24 output ports;

- 2-channel 0-10v analog output Control for VFD or Spindle servo driver

- support DNC processing

-

|

Number of control axes |

3axes (X, Y, Z) |

|

Minimum programming |

0.001mm |

|

Maximum programming |

± 99999.999mm |

|

Maximum traverse speed |

30m / min |

|

Feed speed |

0.001-15m / min |

|

Manual continuous |

one axis or simultaneous multi-axis |

|

Interpolation |

straight line, arc, thread interpolation |

|

Tool offset |

length compensation, nose radius C compensation |

|

Spindle functions |

gear, dual analog control, rigid tapping |

|

Handwheel functions |

panel type, plug-in hand-held |

|

Screen saver function |

screen saver function |

|

Communication function |

RS232, U disk interface |

|

Compensation function |

Tool compensation, Pitch compensation, radius compensation |

|

Program editing |

Relative / absolute programming |

|

Limit function |

software limit, hardware limit |

|

Pre-reading function |

Short line preprocessing 10,000 lines |

|

Password protection |

multi-level password protection |

|

Input and output |

I / O point 24IN / 24OUT |

|

PLC programming |

Programable PLC function |

|

Acceleration and deceleration control |

linear acceleration and deceleration, the number of additions and subtractions |

|

Encoder lines |

any setting |

|

User macro program |

Yes |

|

Electronic gear functions |

Yes |

|

ATC |

Linear/Turret tool changer |

|

Applicable machine tools |

Lathe machine, other SPM machine |

2 Axis Turning Controller-2000 Series

TAC-2002T Turning controller is a new generation of CNC system . As the upgraded version, it supports milling, boring and drilling cycle. It employs 32 bits high-capability CPU and very large scale programmable device FPGA, applies real-time multi-task control technology and hardware interpolation technology, and is able to perform μm level precisionmotion control and PLC logic control

- Model Number: TAC-1002T

- Application: Milling Machine

- Control Axes No.: 2

- Screen Size: 7" Color

- Max. Feeding Speed: 16m/min

- Max. Rapid Travel Speed: 30m/min

- PLC: English Ladder

- Keyboad: Full English

- Macro Program: A type Macro

- Spindle: 0-10v Analog and CS axes

*Three axes control; 2 axes linkage; 2 analog spindles

*ms interpolation cycle, 0.1μm control precision.

*wo channels -10V ~ 10V analog voltage output, support double spindle control

*Linear type, index type and S type etc. acceleration and deceleration types can be chosen.

*Embedded with PLC programming, the current running PLC programming can be chosen

*PLC displayed online, real time monitoring, signal real time tracing

*Supports statement type macro programming, supports macro codes with parameters calls.

*Flexible tapping and rigid tapping can be set by parameters

*Includes spiral, scaling, polar coordinate, fixed circle and a variety of slotting compound cycle function.

*Includes historical alarm and resumen operation functions, it’s convenient for users to operate and maintenance.

*Support multi-level passwords for equipment maintenance and management

*36 point general input/36 point general output

*Support standard RS232 and USB port, support U disk documents operation, system configuration and software

updated, it can meet the functions that documents transfer, serial ports DNC machining and USB online machining

Display interface:

*7.0 inch wide-screen LCD, 800×480 lattice

*Chinese, English etc multiply language display

*2D tool path displays.

*Real-time clock

Operation mode:

*Operation modes: edit, automatic, input, machine tool reset, handwheel/single-step, manual, DNC.

*Multiple operateauthority management.

*Alarm logging

Program edit:

*Program volumn: 56MB, it can store 400 programmings mostly (includes sub-programming, Marco programming)

*Edit function: Programming/programming segment/word retrieval, amend, delete, copy, and stick

*Programming format: ISO code,supports statement macro program, supports relative coordinate, absolute

coordinate and polar coordinate.

*Programming calls: supports maco with parameters calls, level 4 subprogram nesting.

Communication function:

*RS232: parts program, parameters and some documentation two-way transmission, supports PLC program, system

software serial ports update.

*USB: U disk documentation operatiom, U disk processing directly, Support PLC program, system software U disk

update.

*Support serial port DNC processing function and USB online processing function, reliability and safty

Relability and safty function

*Emergency stop

*Handware route limit

*Software routet inspect

*Data backups and Data recover.