Waste Plastic Tyre Rubber Garbage materials into Fuel or carbon or Gas.

Available raw materials of pyrolysis plant - Raw materials and their Oil yield rate at percentage

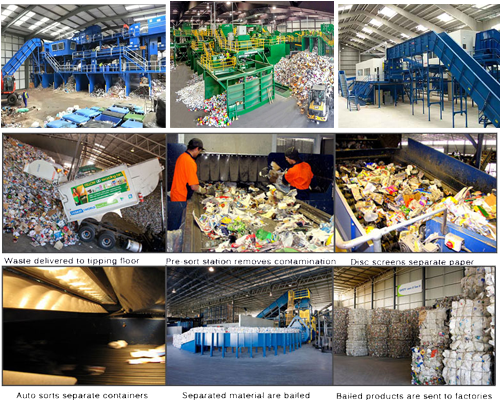

Municipal Solid Waste Sorting Systems

Our municipal solid waste recycling equipment is mainly suitable for the working of urban and industrial solid waste, because the unit adopts the first domestic garbage sorting lines, garbage compactors and docking technology, and the final products are inorganic, organic, irrecoverable fuel, film plastic, ferromagnetic materials and others. The sorting rate of the above garbage can reach more than 85%, the sorting rate of film plastic reaches more than 90%, which will lay a solid foundation for next treatment of “Resource and Industrialize”.

...The Working Process of MSW Sorting as Follows:

- 1. The forklift transports the rubbish into the rubbish bin, and the hopper bottom plate conveyor will take away these rubbishes;

- 2. The garbage will be balanced by ejecting device, and then be sent material layer dial evenly after the first belt conveyor;

- 3. Workers will pick out bulky waste when the garbage goes through the manual sorting platform, at the same time the black metal will be picked out by strong magnetic magnetic separation;

- 4. These rubbish will be separated again by broken drum screen, and will be sorted into two kinds of rubbishes, the diameter greater than 90 mm(plug hole size according to the reality of garbage) on the screen and less than 90 mm undersized material;

- 5. Then the undersize material as raw materials for the system of fat output. The diameter more than 90 mm sieve material will be through the sieve material transport conveyor into other devices (or packed storage).

Main Features of Municipal Solid Waste Sorting System

- High efficiency : The original waste were processed into harmless resource and made to be end products on the same day.

- Innocuity: Fully-enclosed work, no odor leading, no plastics burning, less exhaust gas.

- No remaining: Recycle the waste, treat completely.

- Adaptable: MSW, construction waste, medical waste, dead livestock, food industry waste, agricultural waste.

- Small floor space: one-fourth of composting, one-sixth of landfill. which is completely treated without residual.

- High degree of resources and industrialization: As thoroughly sorting, all materials can be recycled, while reduce the amount of waste incineration and the amount of waste gas.

Technical Data of the Municipal Solid Waste Sorting System:

| Model | BFX-100 | BFX-200 | BFX-400 |

| Raw materials | Municipal solid waste, household waste, industrial waste, landfill waste and mining waste | ||

| Capacity | 5 T/H | 10T/H | 20T/H |

| Power | 149KW | 224.7KW | 279KW |

| Area | 2400㎡ | 2800㎡ | 3000㎡ |

| Working time | 20 hours | 20 hours | 20 hours |

Applications of Final Products:

| NO. | End products | Productivity | Usage |

| 1 | plastic film | 12% | 1.turn to plastic particals to reuse2.pyrolysis to oil |

| 2 | paper | 5% | 1.make pulp to prodce new paper |

| 3 | metal | 5% | 1.smelt new metal |

| 4 | glass | 3% | 1.recovery for reusing |

| 5 | bettary,textle,bulk garbage etc | 5% | 1.recovery |

| 6 | biomass:straw,shell,faeces,food residue etc | 70% | 1.biomass carbonizatin for charcoal |

Waste Sorting Plant

City waste everywhere and no place for garbage, there is no any other solution except bury or burn. Beston waste recycling plant (sorting & Separation) is aimed to reduce the amount of the waste and to turn these waste into treasure. maximize the separation rate of the organic matter, plastic, metal, masonry and other substances from municipal solid waste to improve our life quality.

...How Does Waste Sorting Plant Work:

- First, feeding the garbage into the rubbish bin by forklift,

- Then transported by the plate conveyor to the material even machine, after the garbage are flattened, picking out the large items by human labor.

- Then they will get into the rotary screen to classify the garbage, those items which are smaller than 60mm will be collected to the belt conveyor,generally are organic and stone,

- Then those items are bigger than 60mm will go to next stage, a wind separator. In this machine, they will be classified according to their weight, like plastic and some other combustible items.

- At the end, all the garbage will be packed.

Technical Data of the Waste Sorting Plant:

| Model | BFX-100 | BFX-200 | BFX-400 |

| Raw materials | Municipal solid waste, household waste, industrial waste, landfill waste and mining waste | ||

| Capacity | 5 T/H | 10T/H | 20T/H |

| Power | 149KW | 224.7KW | 279KW |

| Area | 2400㎡ | 2800㎡ | 3000㎡ |

| Working time | 20 hours | 20 hours | 20 hours |

Applications of Final Products:

| NO. | End products | Productivity | Usage |

| 1 | plastic film | 12% | 1.turn to plastic particals to reuse2.pyrolysis to oil |

| 2 | paper | 5% | 1.make pulp to prodce new paper |

| 3 | metal | 5% | 1.smelt new metal |

| 4 | glass | 3% | 1.recovery for reusing |

| 5 | bettary,textle,bulk garbage etc | 5% | 1.recovery |

| 6 | biomass:straw,shell,faeces,food residue etc | 70% | 1.biomass carbonizatin for charcoal |